The Mt Cattlin spodumene project in Western Australia is owned and operated by global lithium mining company Galaxy Resources.

The initial construction of the Mt Cattlin lithium mine began in November 2009 while mining activities commenced in June 2010.

The mining operations were suspended due to market oversupply and a drop in the lithium price. The Australian spodumene concentrate mine was put under care and maintenance during 2013, but operations resumed in 2016 after an increase in spodumene demand and price.

An updated technical report on the Mt Cattlin operations was completed in March 2021. Mt Cattlin produced more than 40,000 dry metric tonnes (dmt) of spodumene concentrate in the second quarter (Q2) of 2021.

Mt. Cattlin project location and geology

The Mt Cattlin spodumene project is located approximately 2km north of the town of Ravensthorpe within the Phillips River mineral province in the state of Western Australia, Australia. The property sits on the mining lease M74/244 which encompasses an area of approximately 1830ha.

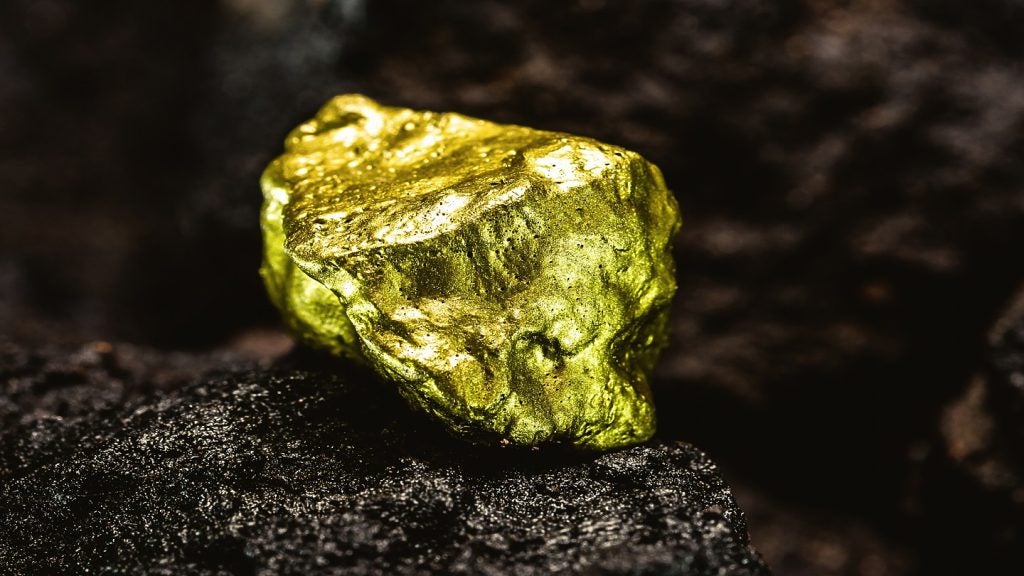

The Mt Cattlin deposit lies within the Ravensthorpe Terrane in a spodumene-rich tantalite-bearing pegmatite. The spodumene host rocks at the property include the Manyutup Tonalite to the east and the Annabelle Volcanics to the west. The lithium-rich pegmatites are found in the form of sub-horizontal sills surrounded by volcanic and intrusive rocks.

Mineralisation and reserves

The lithium and tantalum mineralisation at the Mt Cattlin deposit occurs as a series of sub-horizontal to gently-dipping sills mostly within the pegmatites and as stacked horizons overlapping in sections at some areas. The existing mineralisation extends across approximately 1.6km east-west and 1km north-south with the main pegmatite units generally between 30m and 60m below the surface.

The proven and probable mineral reserves at Mt. Cattlin are estimated at eight million tonnes (Mt) grading 1.04% of lithium oxide (Li₂O) and 139ppm of tantalum pentoxide (Ta₂O₅), as of March 2021.

Mining operations at Mt Cattlin spodumene project

The Mt Cattlin mine operations currently involve a conventional open-pit mining method of drilling, blasting and hauling using backhoe excavators and rear dump rigid trucks. The drilling and blasting are performed in 10m-high benches while the mining operations are carried out on 2m to 2.5m flitches.

The planned pit designs for the remaining mineral reserves at the property comprise two discrete open pits, including the Northeast (NE) and the Northwest (NW) pits. The original main pit of the Cattlin mine known as the Dowling Pit, and the Southwest (SW) and the Southeast (SE) pits have been mined out. The three pits are currently used for waste backfill.

The NE pit is planned to be mined in two stages while the NW pit will be mined in three stages. The initial mining of the first stage of NE Pit was well advanced and delivering ore in early 2021 while mining of the NW Pit is scheduled for mid-2021 with the first stage expected to reach the ore by Q2 2022.

Mineral processing at Galaxy Resources’ spodumene mine

The run of mine (ROM) ore undergoes crushing in a single-toggle jaw crusher and secondary cone crusher and tertiary crushers.

The tertiary crusher product comprising +800µm material is sent to the coarse spiral concentrators while the -800µm material is pumped to deslimes cyclones before being fed to the fines spiral concentrators. The concentrate from both coarse and fines spirals enters a Wilfley Shaker table where the tantalite product is further separated for bagging and dispatch. The waste material from the coarse spirals reaches the ultrafine circuit for further Li₂O recovery.

It is pumped to the wet high-intensity magnetic separator. The magnetic material in the waste is sent to rejects, whereas the non-magnetic material is transferred to a reflux classifier to remove mica. A screw feeder dewaters the classifier underflow and feeds it to the ultrafine dense media separation (DMS) feed bin.

The ultrafine DMS feed is mixed into a ferrosilicon slurry, which is then pumped through the ultrafine DMS cyclone cluster. The resultant product is an underflow of spodumene concentrate from which ferrosilicon is recovered via sieve bends followed by magnetic separation. The spodumene-containing concentrate is sent to the second stage of DMS cyclones to further upgrade the product by removing basalt.

The spodumene product from the secondary DMS undergoes wet screening and the +8mm material is fed to the optical sorter to further remove basalt and produce the final spodumene concentrate.

The final product is drained and loaded into trucks and hauled by road via the South Coast Highway to Esperance Port for bulk shipment to customers.

Project infrastructure for Mt Cattlin

The power supply required for the project operations is provided by dedicated diesel generators under a supply contract with Contract Power Australia.

The raw water needs of the processing plant are met from water bores located on the tenements. A dam adjacent is located near the processing plant to receive the raw water from the bores via pipelines.

Off-take agreements for spodumene concentrate at Mt Cattlin

The spodumene concentrate from Mt Cattlin operations is sold to Chinese companies Yahua Lithium and Sichuan Chengtun Lithium.

The off-take agreement with Yahua Lithium is for the supply of 120,000tpa for a five-year period between 2021 and 2025 while the three-year agreement with Chengtun Lithium is for 60,000tpa between 2021 and 2023.

Contractors involved in Mt. Cattlin lithium mine

Global mining services provider Mining Plus was engaged by Galaxy Resources to prepare the March 2021 technical report.

Australia-based freight and cargo transportation services provider Qube Logistics was contracted to transport the spodumene concentrate from the Mt Cattlin mine to the Esperance Port.